General Specifications

• Heating & cooling capacity between 120–200 kW

• Alternative heating solutions with electric, water coil, and condensing natural gas burners

• Electronic expansion valve (EXV)

• Rotary heat recovery option (condensation & sorption)

• Advanced Carrier control algorithm on air and refrigerant side

• Free cooling with enthalpic economizer

• Advanced Carrier patented defrost control

• High pressure and VAV ventilator and aspirator fan solutions

• High efficiency in Eurovent-certified full and partial loads

• Precise and secure control with smoke, filter, fire, and temperature sensors

• User interface with color touch display

• Standard sandwich panel body with double skin 60 mm isolation

Compressors

• Perfect full and partial load efficiency with multi-scroll compressors and dual refrigerant circuit built-in coils. Refrigerant circuits are electrically and mechanically independent to provide a standby feature in case of a service is needed for a circuit.

• More energy efficiency at partial load for 99% of the work time. Only the necessary compressors are operated. Compressors operating under these conditions are more efficient in terms of energy consumption as they use all condenser and evaporator capacity. An electronic expansion valve at the cooling circuit allows for more secure and efficient refrigerant control.

• Crankcase heaters that are standard for all devices.

Touch Pilot user interface

Touch Pilot is an advanced numerical control system that combines intelligence with superior simplicity in use.

Touch Pilot continuously checks all machine parameters and optimizes to the operation of compressors, fans, and reversing valves for optimum energy efficiency.

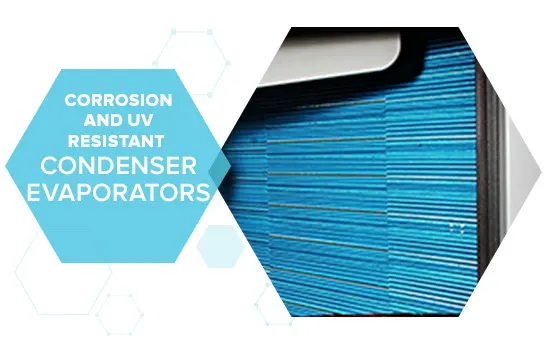

Outdoor condenser/evaporator coil section

• Vertical outdoor coils made of high-quality split copper pipes mechanically connected at pre-coated corrugated aluminum fins with high-level protection against corrosion and UV.

• New generation Flying Bird IV fans that are made of (Carrier-patented) composite material and are more silent do not generate disturbing low-frequency sounds.

• The fan automatically switches to low speed at partial load and low outside temperature, two speed fan motor allows fan adjustment for the best efficiency.

• Defrosting is optimized with an automatic adaptation algorithm. This feature and the new coil design reduce the time for defrosting cycle by an average of 50%. For more security, an electric heater prevents ice accumulation at condenser coil base.

• All pipes and refrigerant parts are welded. Pressure sensors are mounted directly on the pipes.

• Dual inlet indoor fans have forward curved blades.